Fire extinguishing systems

Sprinkler system

Sprinkler systems use water to automatically extinguish fire and are activated by an increase in temperature. Sprinkler is the most commonly used fire protection solution in the world – used in schools, industry, warehouses and many other facilities.

Why choose a sprinkler system?

- High efficiency and reliability

- Activation only in the affected area

- Minimal water damage

- Easy maintenance

How does it work?

Sprinkler nozzles are activated when the temperature rises approximately 30°C above normal. Pressurised water (up to 10 bar) is released instantly, and the system automatically detects a drop in pressure and reports a fire.

Types of systems:

- Wet sprinkler system – for areas with no risk of freezing

- Dry sprinkler system – for areas with extreme temperatures (very low or very high)

Interesting fact

The first sprinkler systems were installed in the 19th century, and in Croatia as early as 1898 in Duga Resa.

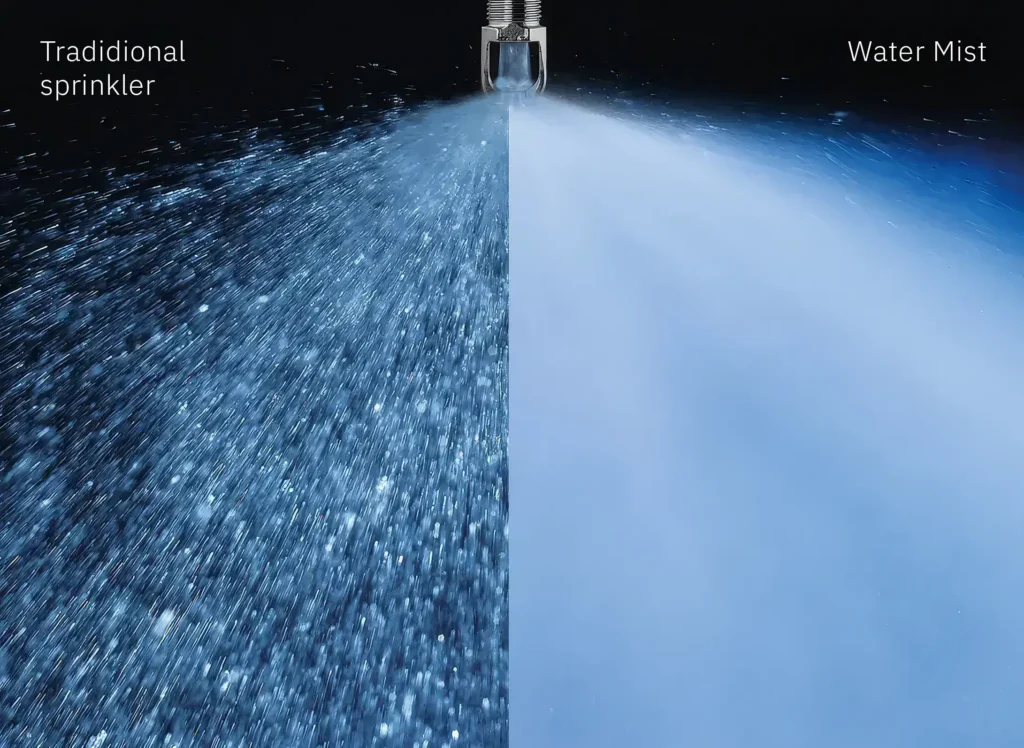

Water mist

The fixed water mist fire extinguishing systems use water under low pressure (12–16 bar) dispersed into droplets of about 1,000 microns in size which quickly turn into steam, effectively absorbing heat and reducing the fire site temperature.

Advantages of water mist:

- Water consumption is up to 85% lower compared to classic sprinklers

- Less damage from water used in extinguishing

- Compact pipes – ideal for buildings with limited space

- Possibility of wet or dry installation depending on the characteristics of the premises

Where is it used?

- Hospitals

- Banks

- Hotels

- Schools and libraries

- Underground car parks

EconAqua in the region

In Croatia, Bosnia and Herzegovina, Montenegro and Macedonia, the authorized partner for EconAqua water mist systems is Aling d.o.o., in cooperation with Viking company.

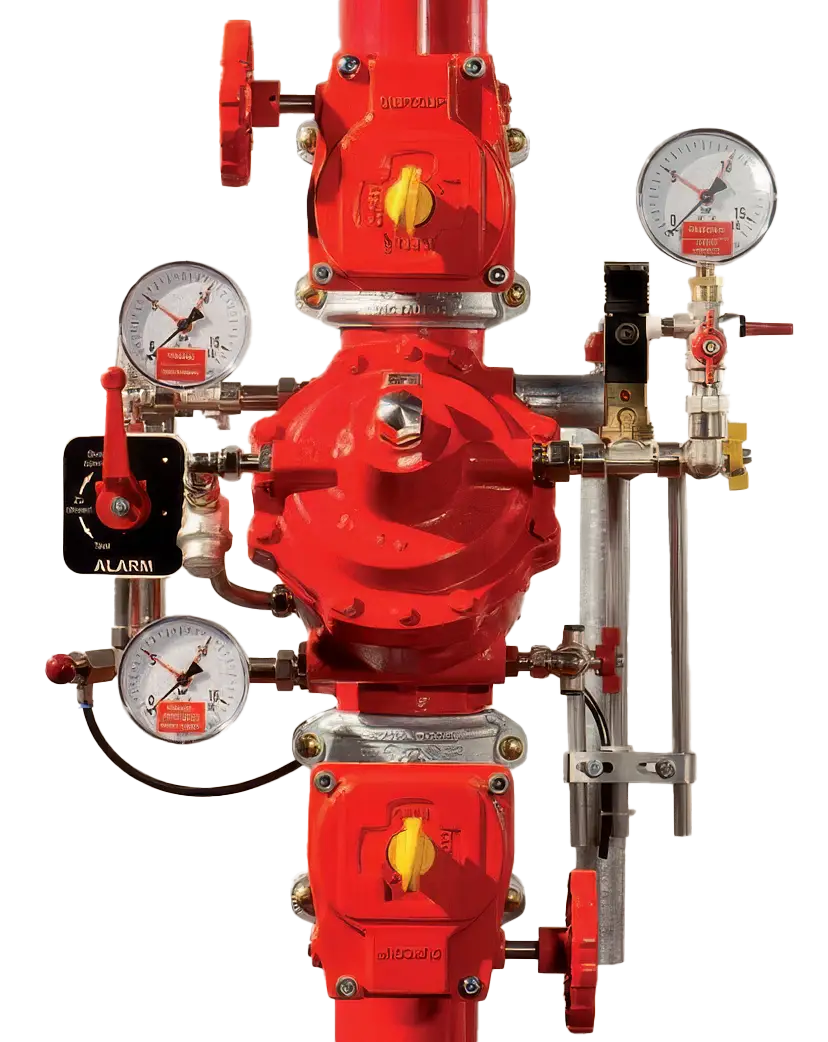

Deluge/Drencher

Deluge systems are fixed fire extinguishing systems, designed for areas with a high risk of rapid fire spread. Unlike sprinkler systems, they use open nozzles that simultaneously release a large amount of water over the entire area.

Key advantages:

- Fast and efficient drenching of the entire area

- Ideal for extinguishing flammable liquids and creating water curtains

- Tank cooling and extinguishing fires in industrial plants

Where is it used?

- Oil and chemical industry

- Fuel storage

- Paint shops

- Recycling plants

- Theatres and areas with technical risks

Activation methods:

- Automatic – via smoke, heat or thermal imaging detectors

- Manual – via control stations

- The signal controls the valve, which opens the water supply for immediate extinguishing

Hydrant networks

Fire hydrant network is a key part of the fire protection system, designed for a quick delivery of water to affected areas via pipelines and firefighting equipment.

Types of hydrant networks:

- Outdoor hydrant network

- with above-ground or under-ground hydrants

- Indoor hydrant network

- with wall-mounted hydrants

Basic requirement:

The indoor network must allow at least one jet of water to cover the entire area.

Indoor network designs:

- Wet network – constantly under pressure and filled with water

- Dry network – empty when not in use; suitable for non-heated or outdoor areas such as car parks and industrial plants

Foam-based extinguishing systems

Foam-based extinguishing systems are ideal for areas with high fire risk, especially where rapid extinguishing over longer distances is required. The foam has a dual effect – it cools and quenches the fire by covering the affected area.

How does it work?

Water and foaming agent are mixed in a ratio of 1–6% in a special mixer, and then the emulsion is delivered to the nozzles where it is mixed with air to make foam ready for extinguishing.

Main components:

- Water and foaming agent tanks

- Pumps

- Mixers

- Pipelines

- Foaming devices

Activation methods:

- Manual

- Automatic

- Remote

CO2 systems

Carbon dioxide (CO2) fire extinguishing systems have been used for decades, and they have a dual function: they reduce the amount of oxygen and cool the space, effectively stopping the fire.

CO2 system applications:

- Chemical industry

- Power plants

- Paint shops

- Warehouses

- Ships and technical facilities

Types of CO2 systems:

- Visokotlačni – CO₂ u bocama pod tlakom 50–60 bara

- Low-pressure system – larger amount of CO2 in a container at -20°C and approx. 20 bar, with a cooling unit

Why choose a CO2 system?

- Reliable and fast extinguishing

- Suitable for protecting the entire area or individual devices

- Affordable complete protection of a facility

FK 5-1-12

FK 5-1-12 is a new generation fire extinguishing gas, developed as an environmentally friendly alternative to halon. It is intended for the protection of areas where water, foam or dust are not suitable.

Advantages of FK 5-1-12:

- Environmentally safe: does not damage the ozone layer, has an extremely low Global Warming Potential (GWP) of 1 and decomposes in the atmosphere within 5 days

- Safe for people: non-toxic, non-dangerous even for people present during activation

- Fast acting: extinguishes fire in less than 10 seconds

- Electrically non-conductive: does not damage electronic equipment

Ideal applications:

- Server rooms and data centres

- Telephone switchboards

- Museums, vaults, archives

- Laboratories and sensitive facilities

Technical characteristics:

- Stored in liquid form under nitrogen pressure (50 bar at 21°C)

- Piping can be placed at a distance of as much as 80 m

- The system must allow complete gas discharge within 10 seconds for effective extinguishing

Gas extinguishing systemsInergen

Inert gas fire extinguishing systems are classified as “clean agent” systems. In practice, the most used gases are IG-100 and IG-55. IG-100 is an inert gas consisting of 100% nitrogen, while IG-55 is a mixture of 50% argon and 50% nitrogen. These gases are stored in containers under a pressure of 300 bar, at a temperature of 21°C.

Advantages of the inergen system:

- Does not damage the ozone layer (GWP = 0) – does not contribute to global warming

- Does not create fog – ensures good visibility during evacuation

- Does not leave residues – no need to clean the area after extinguishing

- Does not create condensation

- Does not cause temperature shock

- Ideal for protecting sensitive equipment, museums and archives

Safety for people:

- Works by reducing oxygen concentration to approx. 12%

- Safe short-term exposure – up to 5 minutes for evacuation

- Does not create toxic by-products during extinguishing

Spark extinguishing systems

Spark extinguishing systems are used in pneumatic conveying systems to prevent the transfer of sparks to flammable material containers and thus avoid an explosion or fire.

How does it work?

The system consists of:

- Spark detector

- Control panel

- Automatic extinguishing unit

Extinguishing is carried out by using pressurized water, which is supplied via a pressure booster connected to the water supply network.

Most common applications:

- Wood industry (sawmills, furniture production, transport of sawdust and wood dust)

- Food industry (mills, drying houses, silos, coffee processing, sugar refineries)

- Coal transport and storage systems

- Plant exhaust systems

- Fertilizer production

- Recycling plants

Kitchen fire protection systems

These systems are specially developed to protect against fires caused by fats and oils, which most often occur on fryers, pans and grills.

Why is it necessary?

Fats ignite at temperatures of around 350°C, and fires can spread very quickly to surrounding equipment and ventilation systems.

How does it work?

- The thermal element automatically detects a temperature increase

- After a short delay, the system is activated and extinguishes the fire by quenching and cooling

- Manual activation is also possible

Ideal applications:

- Professional kitchens in restaurants and hotels

- Fast food facilities

- Canteens, cafeterias and industrial kitchens